- Business

- 소재 사업부

DUST CLANING & CHECK용 매트

King Mat는 PCB, LCD, Lead frame, Glass etching, Film laminating, Film printing 등의 제품 제작 공정에서 발생하는 이물질이나 작업 중 오염된 부분의 이물질을 점착하여 제거하는 제품으로 PM전/후 또는 제품생산 중 투입하여 이물 제거 또는 체크가 가능합니다.

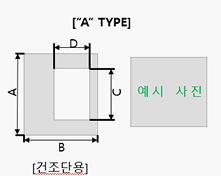

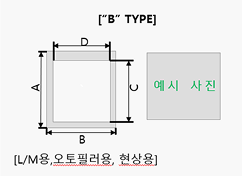

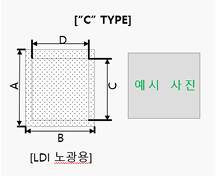

Type A: For drying, Type B: For pretreatment, Type C: For LDI exposure

Type A: For drying, Type B: For pretreatment, Type C: For LDI exposure

| Item | Unit | Kling Mat (GM) | Kling Mat (GM) | Kling Mat (GM) | Kling Mat (CM) | Kling Mat (CM) | Kling Mat (CM) | Kling Mat (HM) | Kling Mat (HM) | Kling Mat (HM) |

| Type | - | A | B | C | A | B | C | A | B | C |

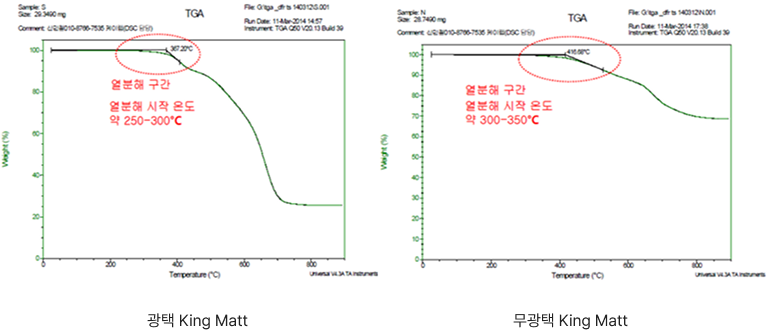

| Application Process | - | General | General | General | Chemical Resistant | Chemical Resistant | Chemical Resistant | High Temperature | High Temperature | High Temperature |

| Adhesion Strength | g/mm | 150±20 | 150±20 | 60±10 | 150±20 | 150±20 | 60±10 | 150±20 | 150±20 | 60±10 |

| Oil Detection | - | No oil transfer | No oil transfer | No oil transfer | No oil transfer | No oil transfer | No oil transfer | No oil transfer | No oil transfer | No oil transfer |

| Surface Roughness (Ra) | ㎛ | Width 4±2 / Length 10±2 | Width 4±2 / Length 10±2 | Width 4±2 / Length 10±2 | Width 4±2 / Length 10±2 | Width 4±2 / Length 10±2 | Width 4±2 / Length 10±2 | Width 4±2 / Length 10±2 | Width 4±2 / Length 10±2 | Width 4±2 / Length 10±2 |

| Operating Temperature | ℃ | Room temp. ~150℃ (30 min) | Room temp. ~150℃ (30 min) | Room temp. ~150℃ (30 min) | Room temp. ~80℃ (30 min) | Room temp. ~80℃ (30 min) | Room temp. ~80℃ (30 min) | Room temp. ~150℃ (60 min) | Room temp. ~150℃ (60 min) | Room temp. ~150℃ (60 min) |

| Water Break Test Criteria | - | Prepare clean CCL surface | Immerse in DI water for 5 sec | Check surface after 10 sec | Check for water marks | Reprepare CCL if marks appear | Use unused CCL | Same specification 기준 | Proceed with evaluation | - |

| Item | Model | Applied Material ① | Applied Material ② | Application Process |

| A | M7510-SS | SUS304 | Silicon | Drying Process |

| A | M7510-SP | Plastic | Silicon | Drying Process |

| B | M7510-SS | SUS304 | Silicon | Laminator / Auto Filler / Developing Process |

| B | M4210-SP | Plastic | Silicon | Laminator / Auto Filler / Developing Process |

| C | M7505-ES | SUS304 | Silicon | LDI Exposure Process |

| C | M7505-EP | Plastic | Silicon | LDI Exposure Process |

Through the privacy policy, the company informs you of the purpose and method of use of the personal information you provide, and what measures are being taken to protect your personal information.

- Self-identification, real name verification, confirmation of subscription intent, use of age

- restricted services according to service use

- Contract performance regarding service provision and fee settlement, content provision, purchase and fee payment, product delivery or sending of invoices, etc.

- Delivery of notices, securing communication channels for complaint handling, securing accurate delivery information when delivering products

- Information for providing the latest information such as new services and providing personalized services

- Other smooth provision of high-quality services, etc.

- Name, company name, email, address, contact information, mobile phone number, inquiry content, and other optional items

- In principle, personal information is destroyed without delay upon achieving the purpose of collection or provision.

- However, in order to provide smooth service consultation, the contents may be retained for 3 months after the consultation is completed, and in cases where preservation is required by other laws such as the Act on Consumer Protection in Electronic Commerce, the information will be retained for a certain period of time.

In principle, the company destroys the relevant information without delay after the purpose of collecting and using personal information has been achieved. The information you entered for membership registration, etc. is transferred to a separate DB (separate file in the case of paper) after the purpose has been achieved, and stored for a certain period of time according to internal policies and other relevant laws and regulations for information protection reasons (see retention and use period) and then destroyed. Personal information transferred to a separate DB will not be used for any other purpose than that for which it is retained, unless required by law. Personal information stored in electronic file format is deleted using a technical method that makes it impossible to reproduce the record.

본 웹사이트에 게시된 이메일 주소가 전자우편수집 프로그램이나그밖의 기술적장치를 이용하여 무단으로 수집되는 것을 거부하며 이를 위반시 정보통신망 이용촉진 및 정보보호등에 관한 법률에 의해처벌 받을 수 있습니다.