- Business

- 소재 사업부

Cushion Pad for Laminated Hot Press

King Board is a cushion pad used in the lamination hot press process for manufacturing precision equipment parts with a laminated structure such as printed circuit boards (PCBs), MLBs, CCLs, etc., discs, IC cards, LCDs, ceramic laminates, etc. It is a product that replaces the currently commonly used kraft paper. King Board is easier to work with than kraft paper that is used by overlapping multiple sheets, and it allows for cost reduction through repeated reuse.

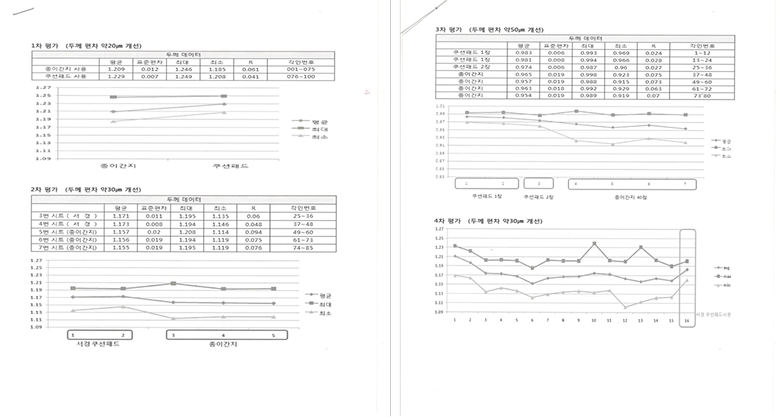

Maintains constant pressure even during repeated use, stabilizing process quality, and maintains cushioning properties even after hundreds of uses, significantly reducing the defect rate.

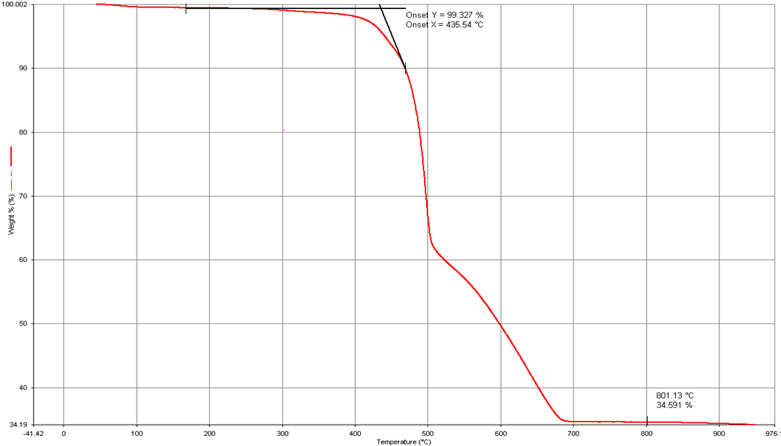

It can be used stably without physical deformation even at high temperatures of 200℃, making it suitable for high-functionality lamination and FPC, CCL processes.

Even pressure distribution ensures stable adhesion to substrate steps and micro-curved surfaces, improving lamination quality.

Compared to paper or multi-layer laminated materials, it produces less waste and is easy to manage, resulting in superior productivity and economy.

Single material composition improves process efficiency by increasing compatibility with automated equipment without complex setup.

It can be safely used in sensitive electronic processing environments such as clean rooms as it does not generate static electricity or foreign substances.

Various specifications can be selected according to the purpose and process conditions (temperature, pressure, etc.), making it easy to design a customized process.

| Item | King Board | Craft Paper |

| Reusability | Up to 200 cycles | 1.7–10 cycles |

| Heat Resistance | Up to 250°C | 150–180°C |

| Automation Compatibility | Compatible | Not compatible |

| Contamination | None | Occurs |

| Cost | Higher initial investment | Increasing cumulative cost |

| Item | Unit | B3515AV-GT21 | B3515AV-CT21 | B3515AV-CA21 |

| Thickness | mm | 1.7–10 | 1.7–10 | 1.7–10 |

| Density | g/cm³ | 1.85 | 1.85 | 1.85 |

| Resilience | % | 75–85 | 75–85 | 75–85 |

| Heat Resistance | °C | Up to 250 | Up to 250 | Up to 250 |

| Surface Resistivity | Ω | 10¹¹–10¹² | 10⁴–10⁹ | 10⁴–10⁹ |

| Maximum Size | mm | Min 1150 – Max 1300 | Min 1150 – Max 1300 | Min 1150 – Max 1300 |

| Reusable Cycles | cycles | 100–300+ | 100–300+ | 500+ |

| Features | - | For Hot Press | For Hot Press | For Lamination (High Elasticity) |

Through the privacy policy, the company informs you of the purpose and method of use of the personal information you provide, and what measures are being taken to protect your personal information.

- Self-identification, real name verification, confirmation of subscription intent, use of age

- restricted services according to service use

- Contract performance regarding service provision and fee settlement, content provision, purchase and fee payment, product delivery or sending of invoices, etc.

- Delivery of notices, securing communication channels for complaint handling, securing accurate delivery information when delivering products

- Information for providing the latest information such as new services and providing personalized services

- Other smooth provision of high-quality services, etc.

- Name, company name, email, address, contact information, mobile phone number, inquiry content, and other optional items

- In principle, personal information is destroyed without delay upon achieving the purpose of collection or provision.

- However, in order to provide smooth service consultation, the contents may be retained for 3 months after the consultation is completed, and in cases where preservation is required by other laws such as the Act on Consumer Protection in Electronic Commerce, the information will be retained for a certain period of time.

In principle, the company destroys the relevant information without delay after the purpose of collecting and using personal information has been achieved. The information you entered for membership registration, etc. is transferred to a separate DB (separate file in the case of paper) after the purpose has been achieved, and stored for a certain period of time according to internal policies and other relevant laws and regulations for information protection reasons (see retention and use period) and then destroyed. Personal information transferred to a separate DB will not be used for any other purpose than that for which it is retained, unless required by law. Personal information stored in electronic file format is deleted using a technical method that makes it impossible to reproduce the record.

본 웹사이트에 게시된 이메일 주소가 전자우편수집 프로그램이나그밖의 기술적장치를 이용하여 무단으로 수집되는 것을 거부하며 이를 위반시 정보통신망 이용촉진 및 정보보호등에 관한 법률에 의해처벌 받을 수 있습니다.